The Supr Shackle:

A Solution for Optimal Lifting

Shackles are essential for connecting ropes, cables, and other lifting slings to cranes and hoists. A pin screws into one lug to secure the loop. For optimal safety and load capacity, the shackle pin and the connected rope or cable should form a perfect 90-degree angle. Unfortunately, traditional shackles have a round pin allows the rope to shift and settle at an angle less than 90 degrees.

This misalignment significantly reduces the shackle’s load capacity. Studies show a capacity loss of 30-50% when the load forms a 45-degree angle or less with the pin centerline.

Addressing the Angling Issue: Stop-Gap Measures and Their Limitations

Construction crews currently use various methods to try and maintain a 90-degree angle:

- Washer Packing: Washers are placed on either side of the eye connection on the pin to center the rope.

- Sleeve Attachments: These add-on devices fit over the pin and have a central depression to center the lifting rope.

Both methods have drawbacks:

- Multiple Sizes Needed: The variety of shackle sizes necessitates a large stock of various washer and sleeve sizes.

- Prone to Loss: These small parts are easily misplaced and unavailable when needed.

The Supr Shackle eliminates the need for stop-gap measures. Its innovative design ensures that the rope or cable attached to the pin automatically forms a perfect 90-degree angle with the centerline, maximizing safety and load capacity.

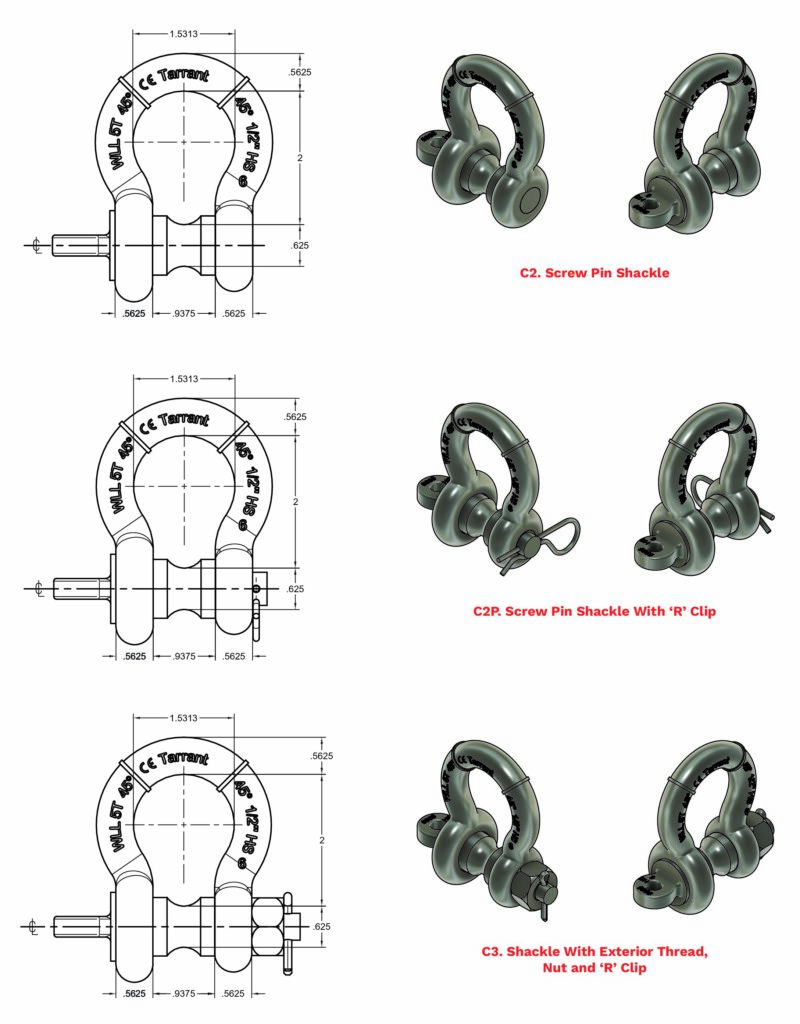

We have three models in each size. We have designed our new universal pin and added a third model in each size.

Typically, there are screw type shackles and bolt type shackles. The bolt type shackles have a hexagon head and need a wrench of a similar size to restrain it while tightening or loosening. Different pin sizes require different wrenches or an adjustable wrench to accommodate different sizes. The screw pin shackle doesn’t have this restriction; there is a hole in the tab at the head of the pin of each size and the tapered handle of any wrench will fit any pin.

We abandoned the hexagon head on the bolt type shackle so now a single tool is all that’s needed to loosen it.

The third model is a screw pin shackle with the added safety feature of a cotter pin, or an “R” clip attached to the end of the pin (C2P)

Supr Shackle

Current Practice

Problem with Current Practice

Current Solutions

Problems with current solutions

Main cause of crane accidents

Features

New Patented Solution

Prevents Flattening

QR Code

Conclusion

Mismatched Spools and Shackles

Tapered Pin

Timed Comparison

Case Studies

Jack Thompson Testimonial

Panel Example

CONTACT US

ABOUT US

As a solution to modern hurdles in construction, Patrick Tarrant designed and patented the Supr Shackle. As a Master Rigger, Patrick has extensive experience in the crane & construction industries.